DSEAR - The Dangerous Substances and Explosive Atmospheres Regulations 2022

Published 13th April 2023

Our latest Blog aims to advise you about DSEAR, the types of activities it covers and how it might affect you. In addition, how you can rely on our knowledge and expertise to ensure you comply:

Fuel Storage Solutions has extensive experience of supplying DSEAR risk assessments to many clients across a variety of industries. It usually follows that work is required to ensure that clients comply to the regulations and this can be carried out by our engineering teams.

We are currently working with:

- The British Military on various military installations in the UK

Fuel Storage Solutions has a great deal of experience carrying our DSEAR risk assessment for the Military. To ensure that we meet the regulatory requirements of DSEAR we utilise various documents including the methodology from the Management of health and safety in defence, JSP 375, Vol 1 Chapter 9 on which we base our DSEAR reporting practices. This gives a clear methodology and documentation to show the procedure for conducting the assessment.

- A client with Data Centres in London where we have inspected 9 sites which include bulk fuel storage and battery UPS storage rooms and subsequently written DSEAR.

Overview of DSEAR and what it means for you

What does DSEAR require?

The primary legislation applies to the control of substances that can cause fires and explosions in the workplace. The full text of the Regulations can be found at the HMSO website as follows:

Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR)

DSEAR requires employers to assess the risks of fires and explosions that may be caused by dangerous substances in the workplace. From June 2015 DSEAR also covers the risk caused by gases under pressure and substances that are corrosive to metals. This is to allow for changes in the EU Chemical Agents Directive the physical hazards aspects of which are enacted in Great Britain through DSEAR. These risks must then be eliminated or reduced as far as is reasonably practicable. The aim is to protect employees and other people who may be put at risk, such as visitors to the workplace and members of the public. The Regulations complement the requirement to manage risks under the Management of Health and Safety at Work Regulations 1999 (SI 1999 No 3242).

Management of Health and Safety at Work Regulations 1999

DSEAR put into effect requirements from two European Directives: the Chemical Agents Directive (98/24/EC) and the Explosive Atmospheres Directive (99/92/EC). It also replaced a number of older regulations dealing with flammable substances safety.

When does DSEAR apply and what does it cover?

Apart from certain activities involving ships, DSEAR applies whenever:

- There is work being carried out by an employer (or self-employed person)

- A dangerous substance is present (or is liable to be present) at the workplace

- The dangerous substance could be a risk to the safety of people as a result of fires, explosions or similar energetic events or through corrosion to metal

The following examples illustrate the type of activities covered by DSEAR:

- Storage of petrol as a fuel for cars, boats or horticultural machinery

- Use of flammable gases, such as acetylene, for welding

- Handling and storage of waste dusts in a range of manufacturing industries

- Handling and storage of flammable wastes such as fuel oils

- Welding or other ‘hot work’ on tanks and drums that have contained flammable material

- Work that could release naturally occurring flammable substances such as methane in coalmines or at landfill sites

- Use of flammable solvents in laboratories

- Storage and display of flammable goods, such as paints, in shops

- Filling, storing and handling aerosols with flammable propellants such as LPG

- Transporting flammable substances in containers around a workplace

- Deliveries from road tankers, such as petrol and bulk powders

- Chemical manufacturing, processing and warehousing

- The petrochemical industry, both onshore and offshore

- Handling, storage and use of gases under pressure

- Handling, storage and use of substances corrosive to metal.

Where does DSEAR apply?

DSEAR applies to workplaces where dangerous substances are present, used, or produced.This includes places such as:

- Industrial and commercial premises

- Land-based and offshore installations

- Mines and quarries

- Construction sites

- Vehicles and vessels

- Places such as the common parts of shared building

- Private roads and paths on industrial estates

- Road works on public roads Some requirements of DSEAR which deal specifically with explosive atmospheres, do not apply to industries such as offshore oil and gas production. See the ‘Explosive atmospheres and ATEX’ section for more information.

Explosive atmospheres and ATEX

What are dangerous substances?

Dangerous substances are substances or mixtures of substances (called ‘preparations’ in DSEAR) that could create risks to people’s safety from fires and explosions or similar events, such as ‘thermal runaway’ from chemical reactions or are corrosive to metal. Liquids, gases, vapours and dusts that may be found in a workplace can all be dangerous substances.

Our methodology for conducting a DSEAR Risk Assessment

Prior to attending site

Prior to the site visit the client is requested to ensure that the following is completed:

- Site is informed of the pending visit.

- Security passes and access to all areas required applicable to the DSEAR assessment.

- Site representatives are available.

- Any additional requirements for site access.

In addition, we ask clients to send electronically/make available any supporting records/documents.

Sources of existing information that may be required to assist/support a DSEAR risk assessment are listed below (list not exhaustive):

| Issue | Existing Records/Documentation |

| Materials Used | COSHH Forms |

| PPE / RPE | Health Surveillance Reports

Health & Safety Risk Assessments |

| Operating Procedures or the process / activity in normal, start-up, shutdown or abnormal operations | SOPs

Operator before use / after use inspections / maintenance |

| Details of operator training | Personnel Training Records |

| Details of fire plans including escape routes | Fire Safety Management Plan |

| Environment and spillage plan as applicable | |

| Details of Hazardous Area

Classification Drawings and marking of hazardous area zones |

If available |

| Existing Controls | Hazardous area register/

Site Safety procedures |

| Signage | |

| Periodic Equipment Inspection | |

| Preventative Maintenance Programme | Maintenance records

Equipment/Platform maintenance regimes. |

| Regular audits and reviews | Audit regime as required |

Risk assessment stage 1

A Stage 1 DSEAR risk assessment must be undertaken (to ascertain if a full DSEAR assessment is required) for any process or activity that is suspected to have the potential to create an explosive atmosphere in normal operation, handling, storage or maintenance; and recorded on the FSS Stage 1 Form.

Risk Assessment stage 2

If the Stage 1 DSEAR risk assessment identifies a possibility of dangerous substances or processes that may result in an explosive atmosphere, then a Stage 2 DSEAR risk assessment must be carried out. The Stage 2 DSEAR risk assessment assesses the fire and explosion risks that may result from the ignition of the dangerous substances. A summary of the residual hazards and risks should be recorded on the FSS Stage 2 report and reference the relevant supporting evidence / documents.

Drawings

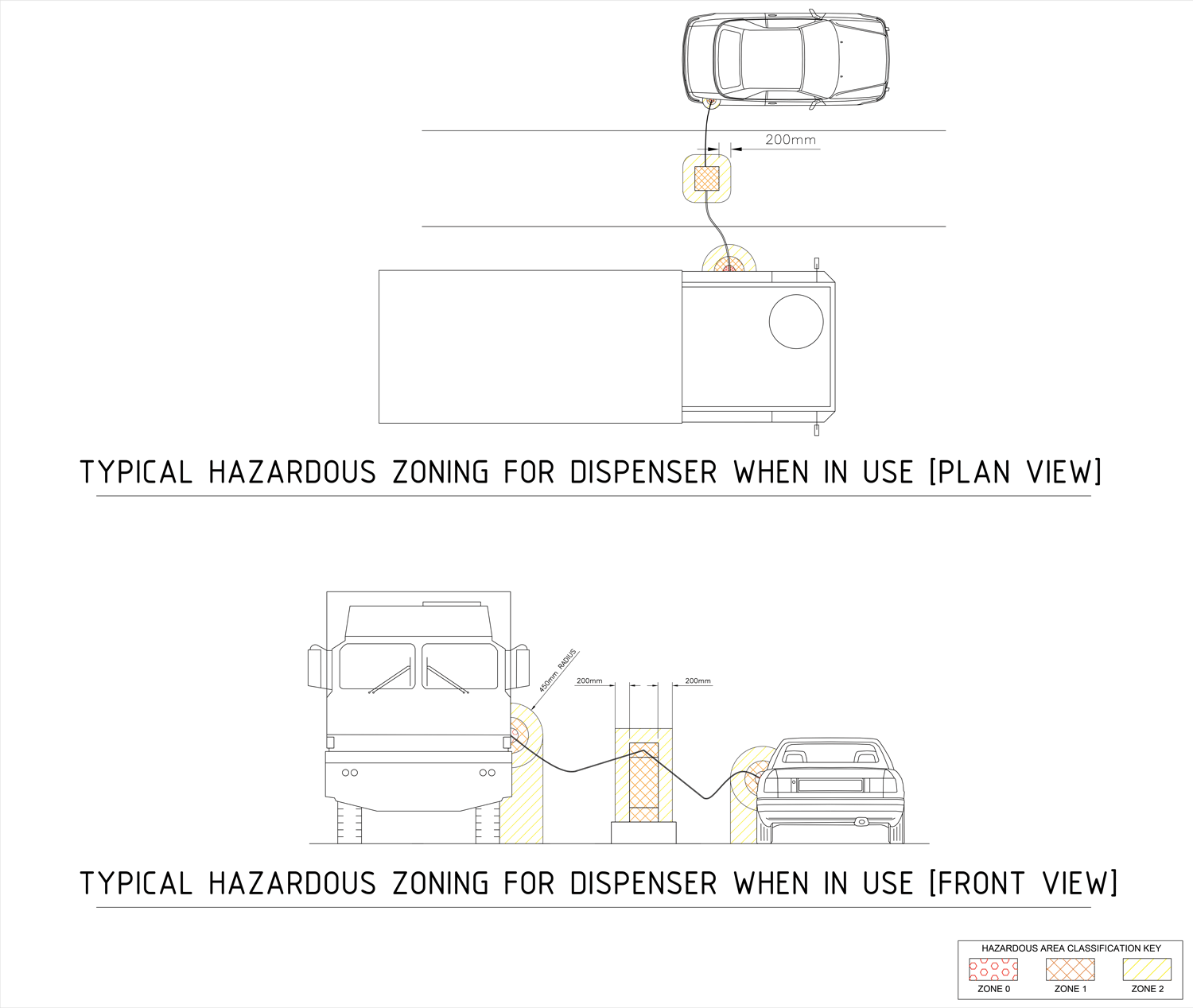

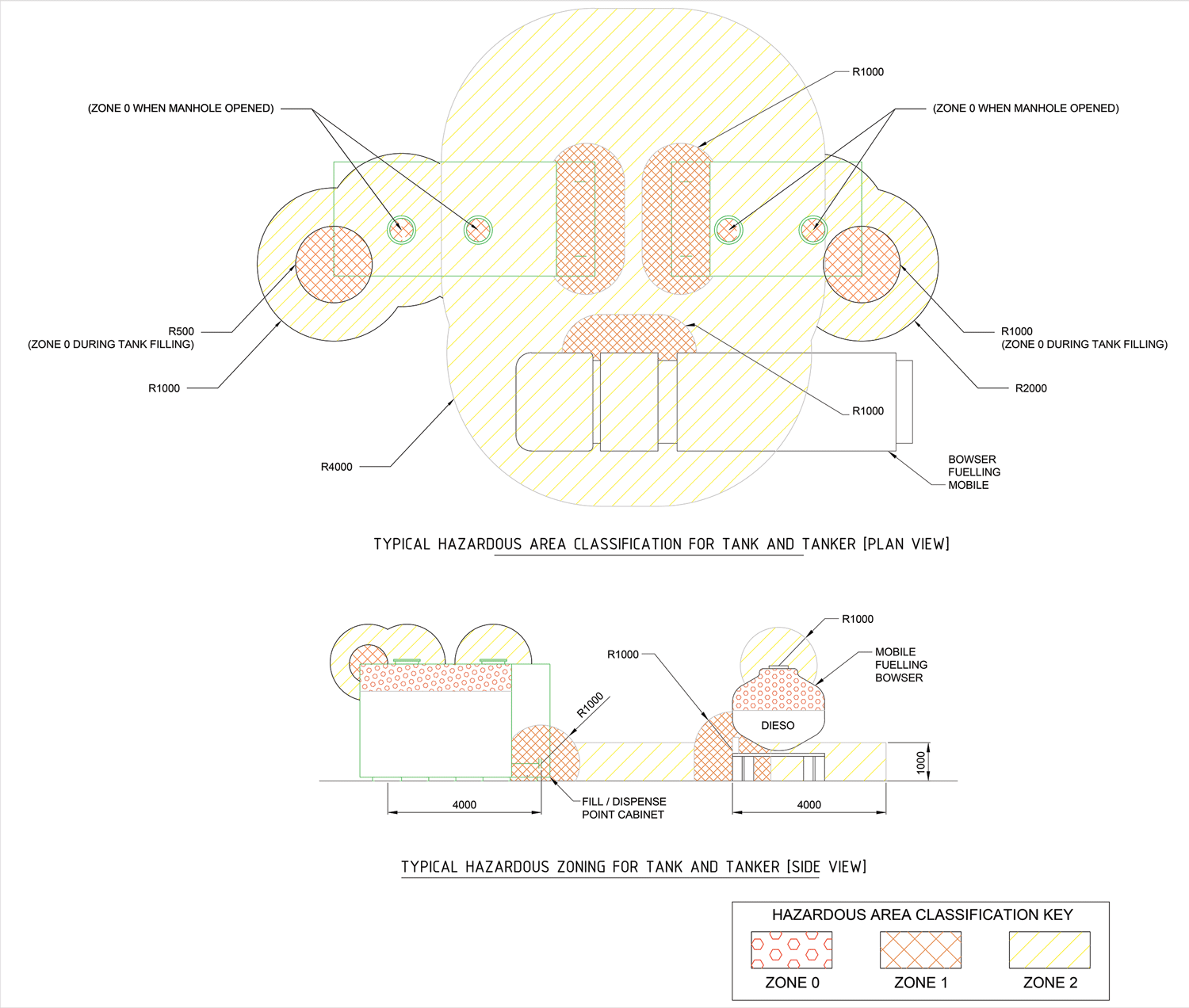

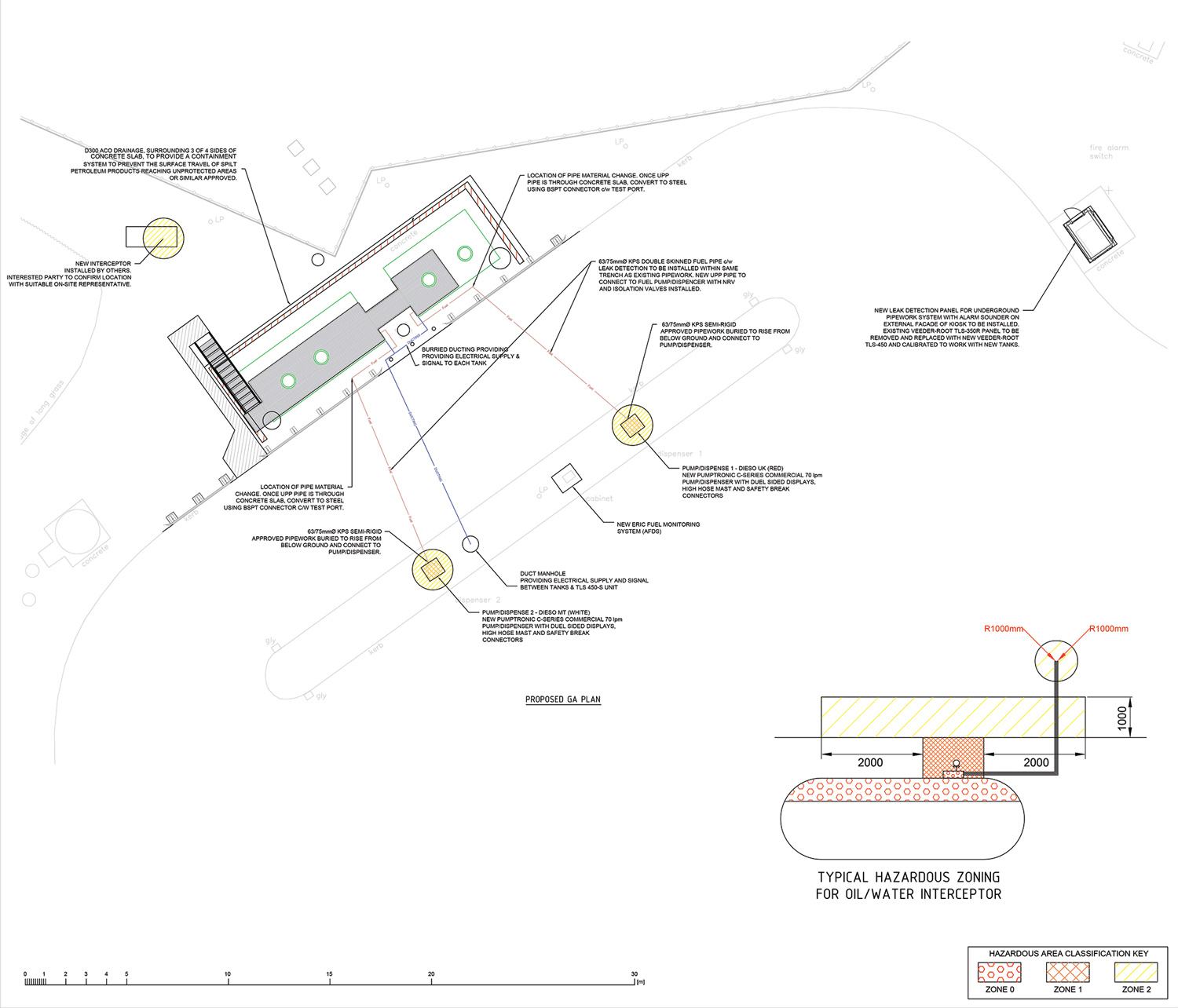

An essential component of the Stage 2 DSEAR risk assessment is the production of hazardous area classification (HAC) drawings.

A hazardous area is defined as a three-dimensional space in which a flammable atmosphere may be expected to be present at such frequencies as to require special precautions for the design and construction of equipment and the control of other potential ignition sources.

The aim of area classification is to avoid ignition of those releases that may occur from time to time in the normal operation of facilities. The approach should always be to reduce the probability of coincidence of a flammable atmosphere and an electrical or other source of ignition and to minimise the extent of the hazard radii.

As the client you are responsible for ensuring that adequate drawings of the site are produced electronically meeting the requirements below and forwarded to FSS prior to the site visit.

For more detailed information please refer to our DSEAR pdf:

DSEAR Download

Book your DSEAR Risk Assessment Today

To book a DSEAR Risk Assessment please call us on 01274 813003.

-

01274 813 003 (normal opening hours: 8.30am to 5.00pm, for emergencies, click here)

-

sales@fuelstoragesolutions.co.uk

Back to Blog

Back to Blog

01274 813 003

01274 813 003 sales@fuelstoragesolutions.co.uk

sales@fuelstoragesolutions.co.uk