Fuel Polishing – your questions answered

Published 24th May 2023

With oil prices unstable, and resources potentially unsustainable, polishing & maintenance of your fuel can keep it within its operating specification almost indefinitely.

Why is Fuel Filtering/Filtration needed?

When oil-based fuel sits in storage tanks for long periods of time the fuel can become unusable. It used to be the case that this fuel had to be disposed of and replaced at significant cost. Now fuels can be reconditioned through polishing and cleaning.

As part of our annual servicing process we sample on site fuel and obtain independent laboratory analyses to assess and monitor its condition.

FUEL STORAGE LIFE:

General Guidelines issued by BP: Under normal storage conditions diesel fuel can stay in a useable condition for:

12 months or longer at an ambient of 20°C

6-12months at an ambient temperature higher than 30°C

As diesel get older it begins to break down. Contact with moisture will eventually lead to a bacterial infection that will render the fuel un-burnable.

Is there a difference between Fuel Filtering/Filtration and Fuel Polishing?

No, they are the same thing but the different terms are used as filtration is typically a one-time pass through a filter (think fuel filter on a vehicle) whereas polishing is set up on a tank to cycle the tank’s contents through filters, often multistage to maintain the fuel in optimum condition indefinitely.

What does Fuel Polishing do?

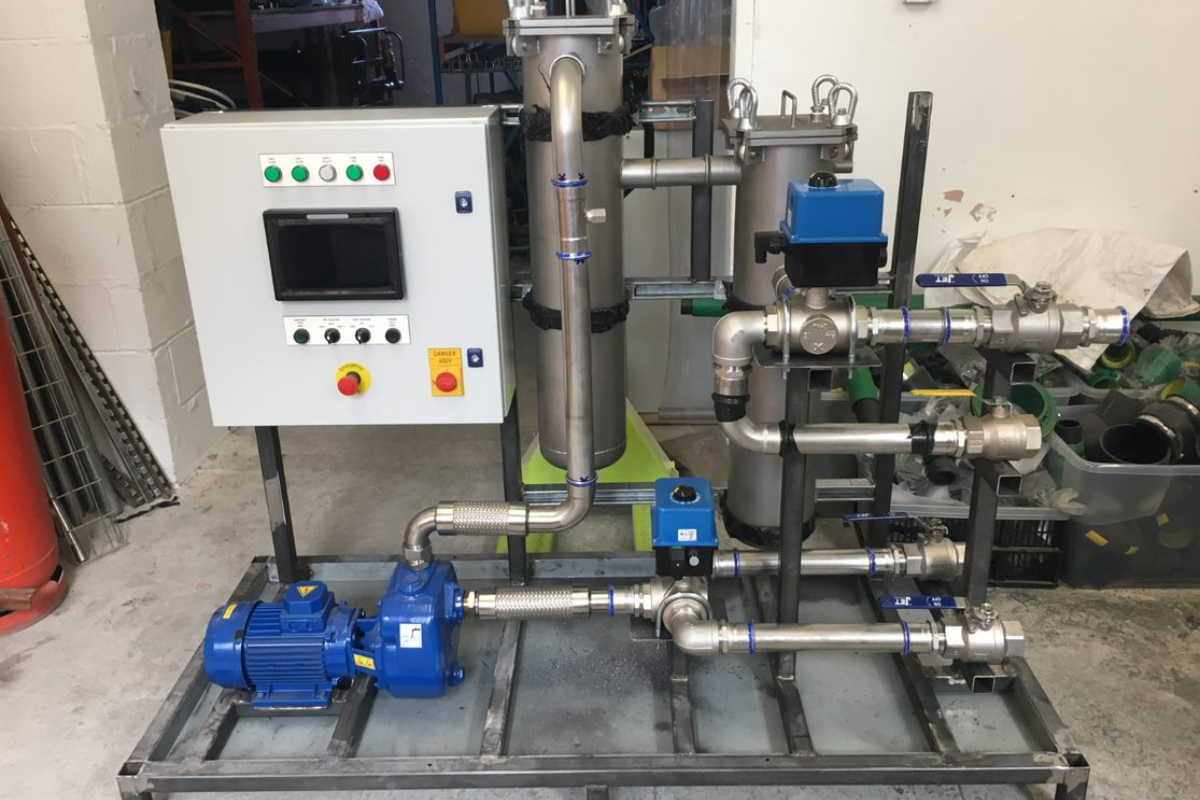

Fuel Polishing is the very fine filtration of diesel fuel to remove impurities of accumulated dirt and particularly water. This is accomplished by pumping diesel fuel from a tank, through a series of filters, and back to the tank. Fuel polishing can collect free and suspended water (suspended is when it has mixed with the fuel) and this will stop the breakdown of the fuel.

An efficient fuel polishing system will be specifically designed to agitate and mix the fuel in the bulk tank, lifting water and contaminants from the tank bottom to enable them to be passed through the polishing system to be removed.

How often should Fuel be Polished?

Unfortunately, there’s no one size fits all answer for this. It is dependent on several factors but in general we would advise that a polishing system is set to turn over the tank (pump its entire maximum volume) through filtration at least once a week. A tank with dirty fuel to start with may be 2 or 3x per week until the fuel is clean then it can be reduced.

Does Bio-Diesel increase the need for polishing?

Since 2010 it is a requirement that all fuel delivered contains up to 5% of bio-diesel to help to reduce emissions. This was increased to 7% in 2011, hence B7 Diesel which means 7% Bio.

The biggest challenge for long term storage of fuel with a bio element is that, due to its organic nature, bio-diesel will attract and hold water, whereas the crude based diesel will repel water. The organic bio element will start to break down when in contact with water, leading to oxidisation, microbial infection and eventually the fuel will degrade to a point of no return.

What are the stages of the Polishing process?

The process removes potentially damaging particulate contaminants and water. With regular filtration this can keep the fuel within its operating specification almost indefinitely. The process we use involves 3 stages:

- Removal of suspended matter in the fuel

- Removal of free and suspended water from the fuel

- Returning to the tank under pressure to create meaningful circulation

Ultimately why is polishing needed?

The fuel in your car gets regularly used, replaced and is constantly being mixed when driving. Bulk fuel tanks, particularly for back up emergency generators may have months or years between deliveries.

Fuel sitting, unmoving and collecting atmospheric moisture will always degrade. These back up emergency systems must operate when required and if the fuel is not maintained then it can cause the whole system to fail when they are actually needed.

Circulate the fuel, remove water and contaminants and make sure that the fuel will be useable when it’s needed most.

Is it possible to pre-plan Fuel Polishing?

When fuel becomes contaminated and is left too long without polishing, the entire tank’s contents may need to be removed and disposed of at a great cost. This is hugely wasteful and environmentally damaging. It is best to continuously maintain your fuel supply to avoid having to dispose of waste fuel.

The responsible and cost-effective solution would be to make use of a maintenance contract and regularly schedule fuel polishing for your fuel system. Such a schedule will work out less expensive and far better for the environment. This service can be carried out by Fuel Storage Solutions.

What are the Key Benefits of Fuel Polishing?

- Fuel will burn when it’s actually needed so systems operate correctly.

- Maintains existing fuel rather than having to dump and replace stocks so is far cheaper

- Prevent water from mixing with the fuel ensuring the fuel will burn efficiently.

- Prevents blocked fuel filters and seized fuel pumps.

Depending on your generator set-up, diesel fuel polishing systems can be connected to your fuel supply and can run the filtration process while causing no disruption to your day-to-day operations. This means that your contingency power supply can continue to be called upon at any given moment.

To book a one-off Fuel Polishing application or to arrange an annual maintenance contract please call us on 01274 813003.

01274 813 003

01274 813 003 sales@fuelstoragesolutions.co.uk

sales@fuelstoragesolutions.co.uk Back to Blog

Back to Blog

01274 813 003

01274 813 003 sales@fuelstoragesolutions.co.uk

sales@fuelstoragesolutions.co.uk